Our Approach

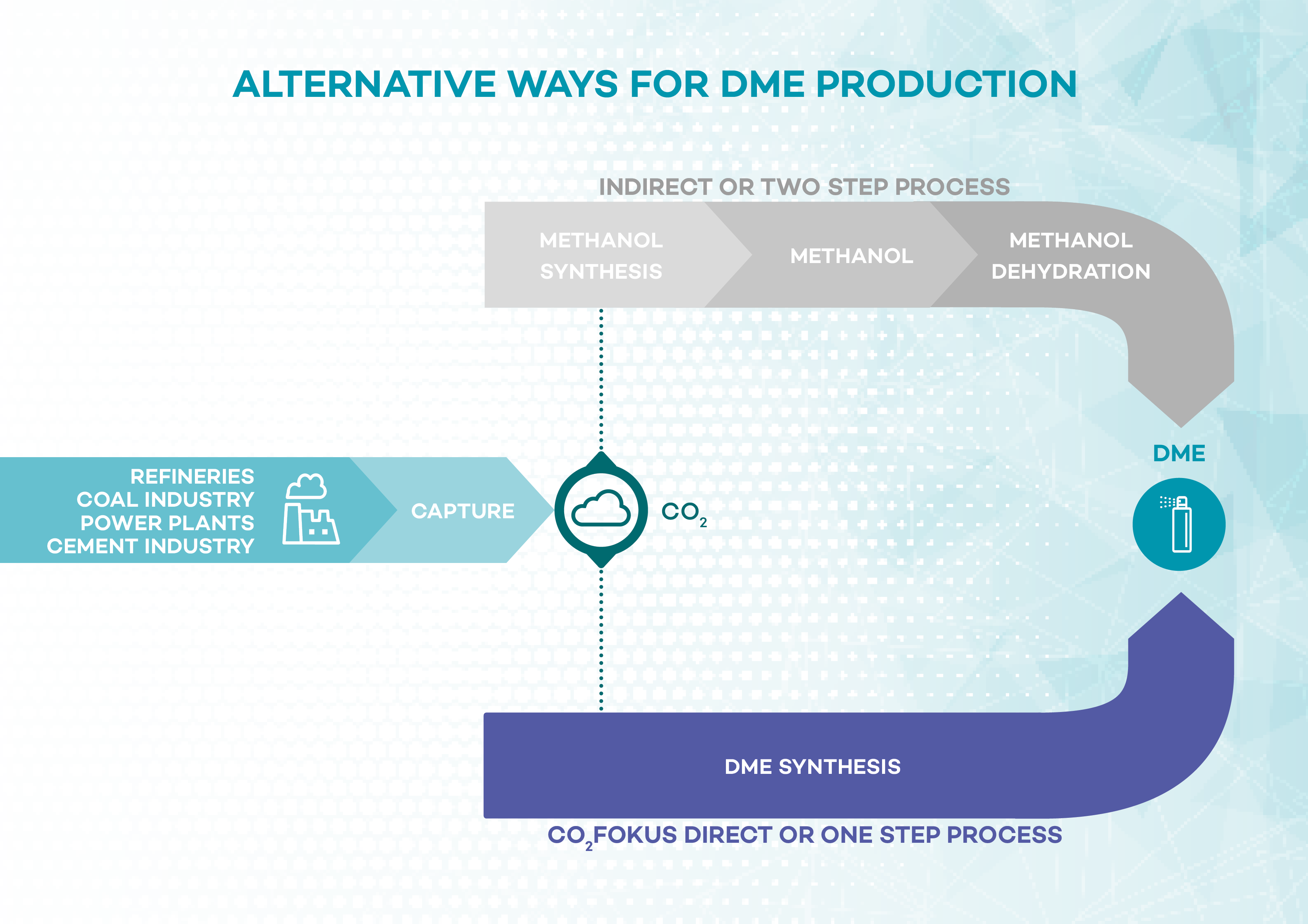

Currently, DME is commercially produced through an indirect, two-step process involving the production of methanol and its subsequent dehydration. This process is energy intensive and requires substantial capital and infrastructure investments.

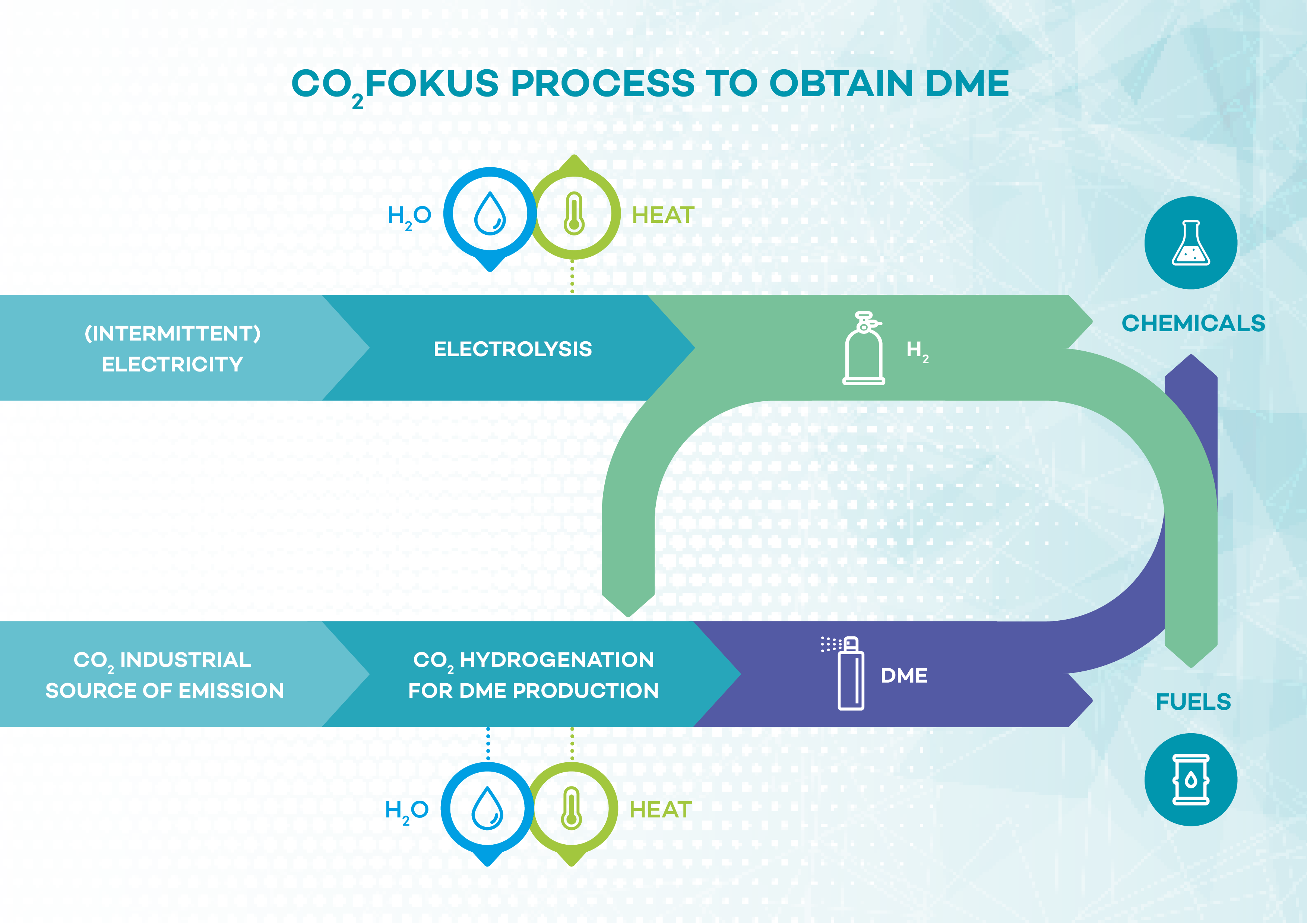

CO2FOKUS will demonstrate the viability of a single-step process involving the direct and continuous synthesis of DME from industrial CO2 and H2 in a more efficient way.

This will involve both catalytic chemical and electrochemical conversion through innovative multichannel catalytic reactors and solid oxide electrolyser cells. Multichannel reactors will be developed and manufactured by project partners using 3D printing techniques, and subsequently tested in an industrial environment with a CO2 point source.

Attention will be given to both the process itself and, more widely, to its economic evaluation and expected environmental and social impacts, to maximise the likelihood of its successful application. This will encourage the adoption of the technology and allow the integrated CO2FOKUS systems to be easily deployed in existing plants.

THE CO2Fokus project consists of several steps

1 Catalyst development:

2 Reactors development:

Development of structured multi-channel reactors with optimal characteristics for DME production. Their design will incorporate novel 3D printing technologies, to lay down functional material with high fidelity and near exact repeatability.

3 Solid oxide electrolyser cell and co-electrolysis system development:

Development of solid oxide electrolyser cells, to convert CO2 and H2O to a mixture of CO and H2 required for DME synthesis in the catalytic reactor.